Product Details

Features:

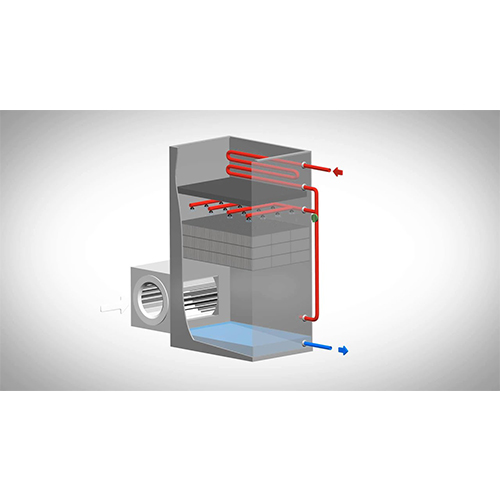

Quantitatively, the material adjust around a half and half cooling pinnacle is administered by the operational factors of make-up volumetric stream rate, vanishing and windage misfortunes, draw-off rate, and the focus cycles.

The water pumped from the pinnacle bowl is the cooling water directed through the procedure coolers and condensers in a modern office. The cool water ingests warm from the hot procedure streams which should be cooled or dense, and the retained warmth warms the coursing water. The warm water comes back to the highest point of the cooling tower and streams descending over the fill material inside the pinnacle. As it streams down, it contacts surrounding air ascending through the pinnacle either by characteristic draft or by constrained draft utilizing huge fans in the pinnacle. That contact makes a little measure of the water be lost as windage/float and a portion of the water to dissipate. The warmth required to dissipate the water is gotten from the water itself, which cools the water back to the first bowl water temperature and the water is then prepared to recycle. The vanished water abandons its broke down salts in the majority of the water which has not been dissipated, in this manner bringing the salt focus up in the flowing cooling water. To keep the salt grouping of the water from winding up too high, a bit of the water is drawn off/blown down for transfer. New water make-up is provided to the pinnacle bowl to make up for the loss of vanished water, the windage misfortune water and the draw-off water.